Club de muestras

Embalaje de papel o cartulina cortado por láser

Papel

Introducción

Embalaje de papel o cartulina cortado por láser

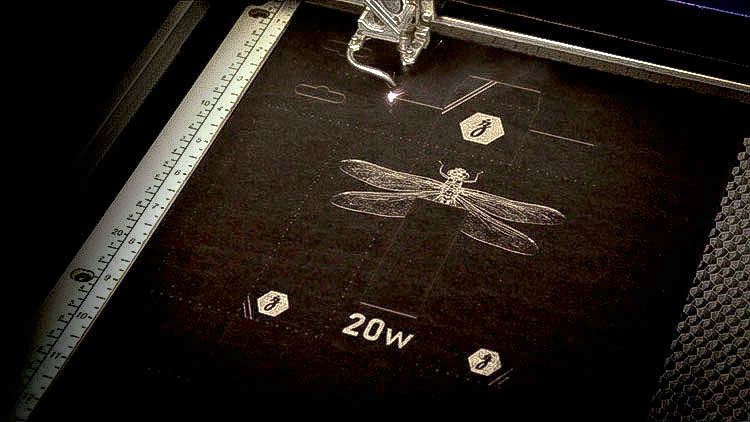

La cartulina es un material muy versátil y popular para la aplicación del láser, ya que puede cortarse y grabarse. Este proyecto del Club de muestras está creado con cartulina negra grabada y cortada para crear un embalaje personalizado para bombillas. Mediante el ajuste de la velocidad, potencia y frecuencia del láser, los operadores pueden grabar texto, cortar formas e incluso crear líneas perfectamente perforadas para doblar y montar con mayor facilidad. Siga leyendo para saber cómo terminamos este proyecto. ¡Lo alentamos a que considere incorporar el corte láser de embalaje a su línea de productos!

ajustes de proyectos

Materiales necesarios

-

Pegamento

Máquina usada

Helix 60w

Proyectos recientes

velocidad

potencia

PPP

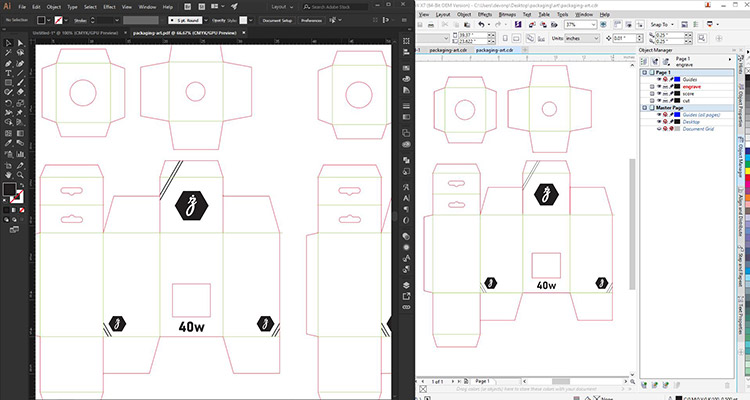

Preparación del diseño

Descargue los diseños de arriba e impórtelos a su software de diseño gráfico. Haga los ajustes necesarios.

Enviar al láser

¡Envíe el trabajo al equipo láser con los parámetros correctos para el vataje del equipo.

Montaje

Saque el embalaje de la plantilla y luego doble y arme las cajas de papel. Use pegamento en el interior de la aleta.

¿Dónde puede vender el embalaje de papel personalizado grabado por láser?

- Bodas/eventos especiales

- Eventos corporativos/fiestas

- Para dueños de empresas

- Tiendas de especialidades

También le podrá gustar...

Relacionado con: Papel